PET Container

With a variety of products,

Samyang Packaging will offer you

true customer satisfaction.

Semi-finished products injection molded to manufacture final PET bottles.

Samyang Packaging has the lightest weight perform for spring water in Korea and the largest capacity in the production of the multi-layer preform in Korea. We also produce and supply a diverse range of preforms with its specialized technology.

Products

Normal Pressure

-

- Mouth Type

- Mineral Water, 30 Regular

- Weight (g)

- 13.5, 14.2, 15, 17, 20, 31, 36.2, 38, 43, 47, 51

-

- Mouth Type

- Mineral Water, 30 Short Cap

- Weight (g)

- 11.1, 29.6, 32.6

-

- Mouth Type

- Takju (Rice Wine)

- Weight (g)

- 34

Pressure-Resistant

-

- Mouth Type

- PCO 1810

- Weight (g)

- 18, 23, 28, 46, 46.5, 52

-

- Mouth Type

- PCO 1881

- Weight (g)

- 24, 31.6, 41, 43

Heat & Pressure Resistant

-

- Mouth Type

- Alcoa

- Weight (g)

- 17, 29, 33, 36.5, 47, 51, 57, 61, 64, 68

-

- Mouth Type

- PCO

- Weight (g)

- 23, 27, 28, 32

-

- Mouth Type

- Ø38, Crystallized

- Weight (g)

- 29, 33, 59, 67

-

- Mouth Type

- Ø38, Uncrystallized

- Weight (g)

- 30, 35, 62.5

Special

-

- Mouth Type

- Multi (PCO 1810)

- Weight (g)

- 20, 24, 36, 43, 48, 52

-

- Mouth Type

- Aseptic, Ø38

- Weight (g)

- 20, 22, 24, 44, 46

-

- Mouth Type

- Aseptic, Ø38

- Weight (g)

- 28, 32,

33 (For heating cabinets_Crystallized Neck), 53

Packaging material for food and beverage products and daily supplies with durability, heat and pressure resistance, transparency and excellent recyclability.

Since Samyang's PET bottles are widely recognized for their unique qualities of non-toxicity, transparency, preservation, and resistance to pharmaceuticals, they are increasingly being used as a substitute for glass and aluminium cans both domestically and internationally. In particular, PET bottles have been identified as excellent food containers that are free from environmental hormone issues.

Characteristics

-

Harmless

to human bodyThe PET Bottle, approved

by the FDA for perfect non-toxicity, is a sanitary container that has passed various standard sanitary tests and is also safe from environmental hormones. -

Use of materials that enable long-term preservation

Compared to other plastic containers, the volume of oxygen, carbon dioxide, and water vapor can be extremely low, so they can be stored for several months or more without any deterioration of the contents.

-

Stability with low risk

in case of breakageAfter filling it with content,

it boasts excellent safety that does not break even if dropped from a height of 2 meters and does not generate fragments even when forcedly damaged

by a physical external force. -

Designed containers

with beautiful appearanceIt is much clearer than glass bottles and other plastics, allowing the contents to stand out.

-

Easy to handle due

to the lightweighting.Since it weighs only one-thirteenth to one-fifteenth of a glass bottle, handling it is easy and logistics costs are saved.

-

Eco-friendly containers

that are easy to recycleClean containers that can be completely combusted and do not generate harmful substances such as dioxins.

Products

Production

Process

-

01 Solid-State Polymerization

A process that gives the resin a viscosity that is proper for elongation.

-

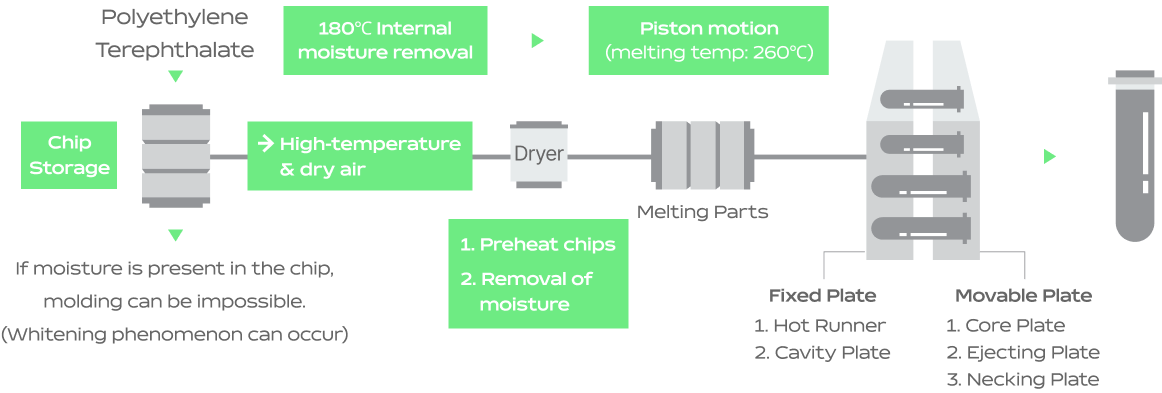

02 Injection

A process of producing a basic form (i.e., Preform) that is proper for elongation.

-

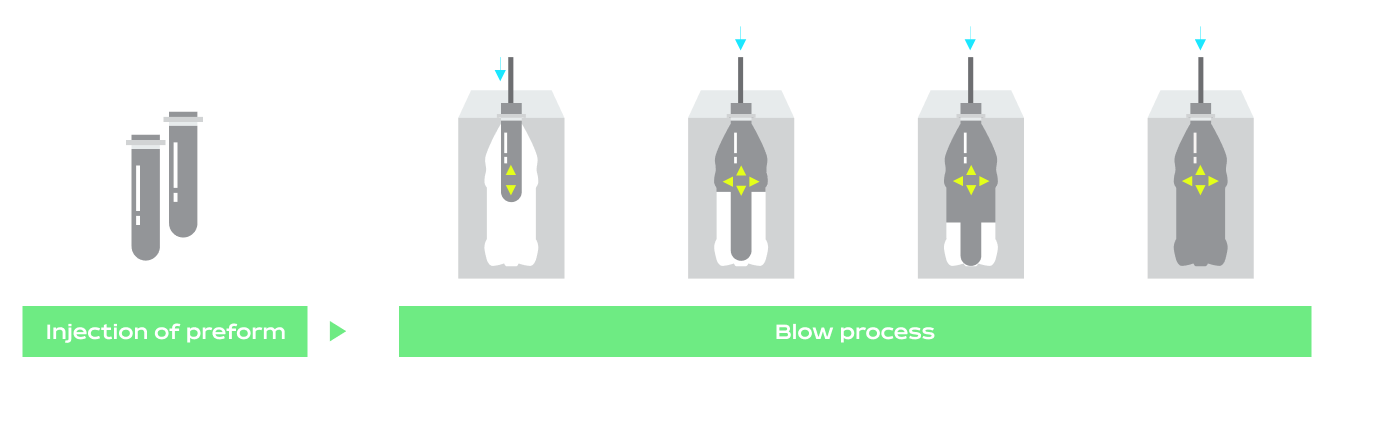

03 Elongation

The process of completing the bottle by blowing high-pressure air into the mold after heating the injected preform to make it easier to stretch.